Introduction to the production process of high-speed rail cabins

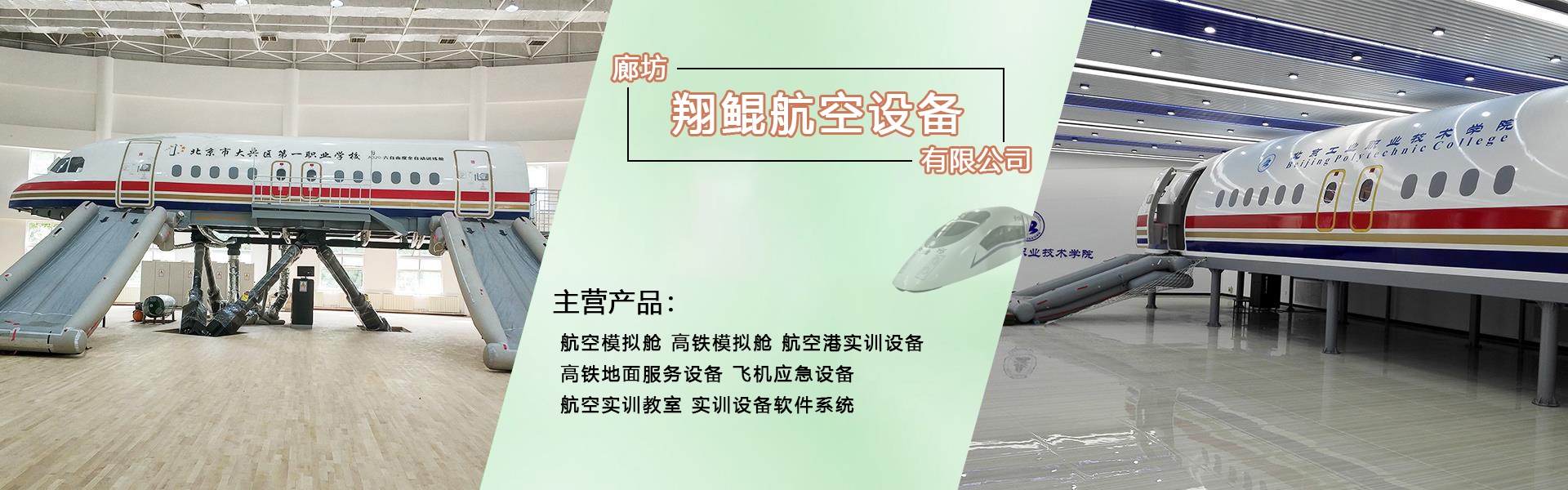

Langfang Xiangkun has been engaged in the production and sales of aircraft education imitation cabins and high-speed rail education imitation cabins for many years. In this article, we will introduce the production process of high-speed rail cabins. Let's take a look.

The manufacture of high-speed rail cabin training equipment models is roughly divided into four processes, which are:

1. Manufacture the body floor and keel structure: the standard size of the car body is 1:1, the carriage and the front of the car are divided into 2 sections, the actual length is 17 meters after the manufacture, and the main body material is 3030mm square steel, cut, welded, polished, welded and polished. After the completion, the body and the head are connected with bolts, so as to prevent the faulty connection as much as possible without displacement.

2. Skin laying on the outside of the car body: The external skin laying of the car body is fixed on the frame by 1.5mm thin plate welding. The material is cut by laser cutting to ensure accurate size and numbered according to the orientation of the car body. After completion, assemble and weld according to the serial number. , Special-shaped surfaces such as the arc-opening surface of the car body are rolled and formed by a plate rolling machine, and the whole welding is completed and then polished.

3. Brushing fiber putty powder grinding and spraying: The spraying process uses baking paint spraying and imported metal paint for spraying, and then spraying treatment after multiple grinding in the early stage. In order to ensure the strength of the paint, fiber putty is scraped in the early stage, and the surface is brushed after dry grinding. The final process of spraying is to use the water grinding process to carry out detailed and detailed grinding of the parts of the car body that need to be sprayed, spray the primer and then apply the topcoat to finish the surface finish.

4. Interior interior installation of the car body: The driver's control console in the front of the car is strengthened in the early stage. In order to ensure that the processing accuracy of the control console is similar to that of other objects, 3D printing is used, and it is polished and colored after grinding and lubrication.

The above is the introduction to the production process of the high-speed rail cabin that we have introduced to you. I hope it can help you. If you need to know more, you can leave us a message or call to communicate.