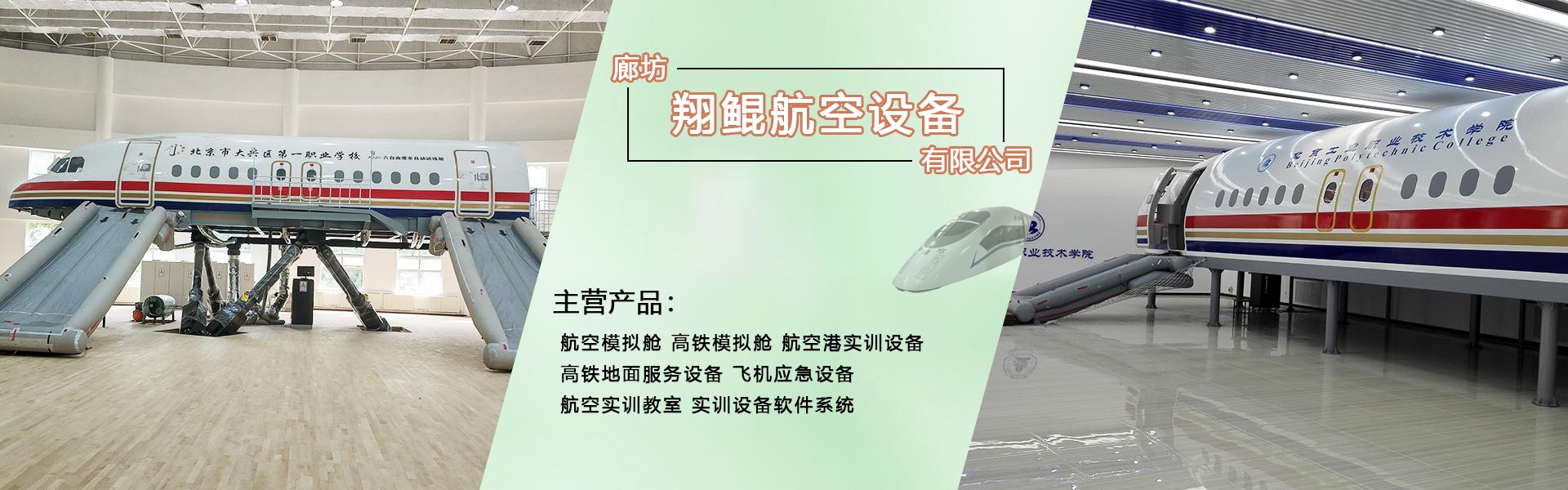

The composition of the high-speed rail cabin

The reform of the talent training model focuses on the practicality of the teaching process, the openness and professionalism of the high-speed rail cabin, experiment, practical training, and practice are the three key links. On the basis of theoretical teaching, the content, methods and means of practical teaching should be reformed as a whole. , establish a new practical teaching system integrating knowledge, ability and quality. Inherit the modern education concept of "knowledge, ability and quality" coordinated development and comprehensive improvement, establish the idea of "student-centered, serving students", in order to strengthen students Quality and practical education are the main line, and students are trained with the core goal of cultivating talents with engineering practice and innovation ability.

Generally speaking, high-speed rail cabins can make students more proficient in practical operations. How to serve, how to deal with some emergencies from boarding to getting off can all be practical training. And the combination of theory and practice can more effectively Book knowledge is transformed into practical experience to achieve the effect of applying what you have learned, and prepare for work.

The composition structure of the high-speed rail cabin is mainly composed of the following contents:

1. Cab frame: According to the design of the Fuxing high-speed rail, it is simulated and produced at a scale of 1:1. The frame is composed of a beam frame and a frame plate, and the appearance of the beam frame and the frame plate is formed by numerical simulation and fiber cutting.

2. The outer wall of the engine room: the outer wall is a thick-walled shell structure, and the transverse prefabricated components are laser-cut from thick steel plates, welded on the basis of ensuring the size, and the longitudinal and transverse prefabricated components are welded into one. The outer skin is made of high-quality galvanized steel plate , Riveted with the frame, longitudinal beam and beam to ensure that the cockpit has sufficient compressive strength and bending rigidity.

3. Floor skeleton: Weld several skeleton screw devices, each of which is made of high-quality alloy steel. The floor frame is connected with the floor by screws. For the convenience of assembly, the floor skeleton is paved with 18 mm high-quality double-layer board, which makes it have sufficient resistance to Compressive strength and bending stiffness.

4. Rear end plate: It is composed of skeleton and galvanized steel plate. The frame is made of high-quality alloy steel and welded with the inner hole frame behind the cockpit. The frame is welded with galvanized steel plate to enhance the airtightness of the engine room.